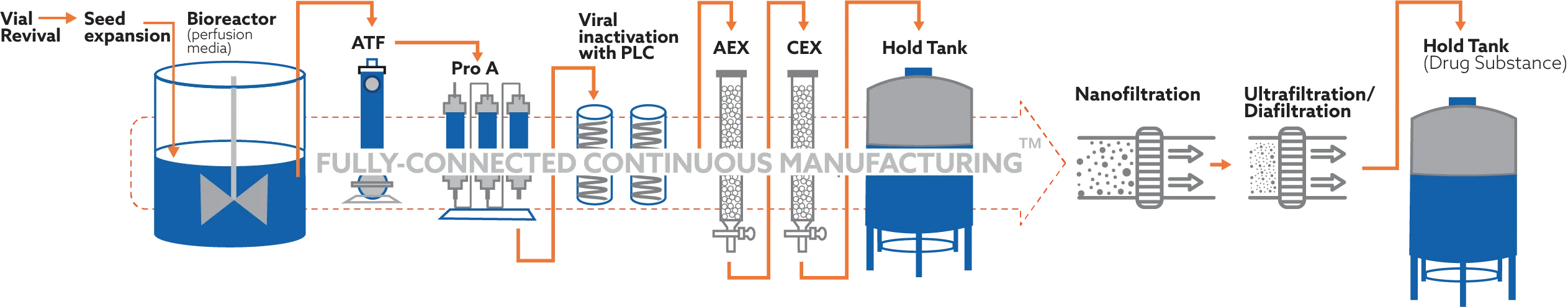

Fully-connected continuous manufacturing™ (EnzeneX™)

Unlocking higher yields across a range of biologics at significantly lower costs to you, our patented fully-connected continuous manufacturing™ (FCCM™) platform represents the pinnacle of our ongoing commitment to innovation.

What is EnzeneX™?

EnzeneX™ is an advanced fully-connected continuous manufacturing™ platform that harnesses the power of intensified perfusion using alternate tangential flow (ATF) and automated multi-column chromatography to achieve continuous production of biologics.

Designed for efficiency and cost-effectiveness, EnzeneX™ enables uninterrupted loading and processing of materials, delivering superior product quality and manufacturing outcomes.

What can EnzeneX™ do for you?

High-quality production

EnzeneX™ minimizes product contact with cell culture fluid, ensuring high-quality manufacturing. This is crucial for biologics that are prone to degradation including less stable and difficult-to-express proteins.

Cost-effective manufacturing

EnzeneX™ reduces processing costs by approximately 50%, providing you with cost-effective manufacturing. This is achieved with a lower cost of goods and efficient use of resources.

Adaptable design

EnzeneX™ provides flexibility with a minimum 30-50L supply.

The modular and variable bioreactors enable scale-on and scale-out flexibility, allowing you to adapt to changing production needs and optimize your manufacturing capacity.

Increased productivity

EnzeneX™ increases your manufacturing productivity, achieving approximately 10 times higher productivity than traditional fed-batch manufacturing

Reduced emissions

EnzeneX™ increases sustainability by reducing the equipment footprint and carbon footprint of manufacturing processes.

How does EnzeneX™ work?

Discover the science behind our patented and fully validated fully-connected continuous manufacturing™.

EnzeneX™ has enabled us to successfully manufacture commercial monoclonal antibodies (mAbs) and convert biologics from fed-batch production to FCCM™.

Uncover the unique advantages of EnzeneX™

Fully-connected continuous manufacturing™

- EnzeneX™ utilizes a patented combination of intensified perfusion and multi-column chromatography, ensuring the highest quality, efficiency, and cost-effectiveness in manufacturing

- This innovative process enables consistent and reliable production of biopharmaceutical products

Primed for product scaling

- EnzeneX™ offers scalability options, allowing you to transition from small-scale production to commercial manufacturing

- Two scaling options are available:

- Scale-on: Uses the same-size bioreactors with a higher process duration

- Scale-out: Involves multiple same-size suites, providing increased capacity

Designed with flexibility in mind

- EnzeneX™ prioritizes flexibility, enabling you to adapt to the changing demands of your biologics products

- This offers lower costs when scaling up or down production and improved sustainability by reducing carbon emissions and facility footprints

Join the EnzeneX™ revolution

Fueled by our continuous innovation and armed with EnzeneX™, our fully-integrated CDMO solutions and our biosimilars pipeline are designed to help bring your biologics innovations to life.